Products

- Grinding

- Turning

- Milling

- Remote Monitoring

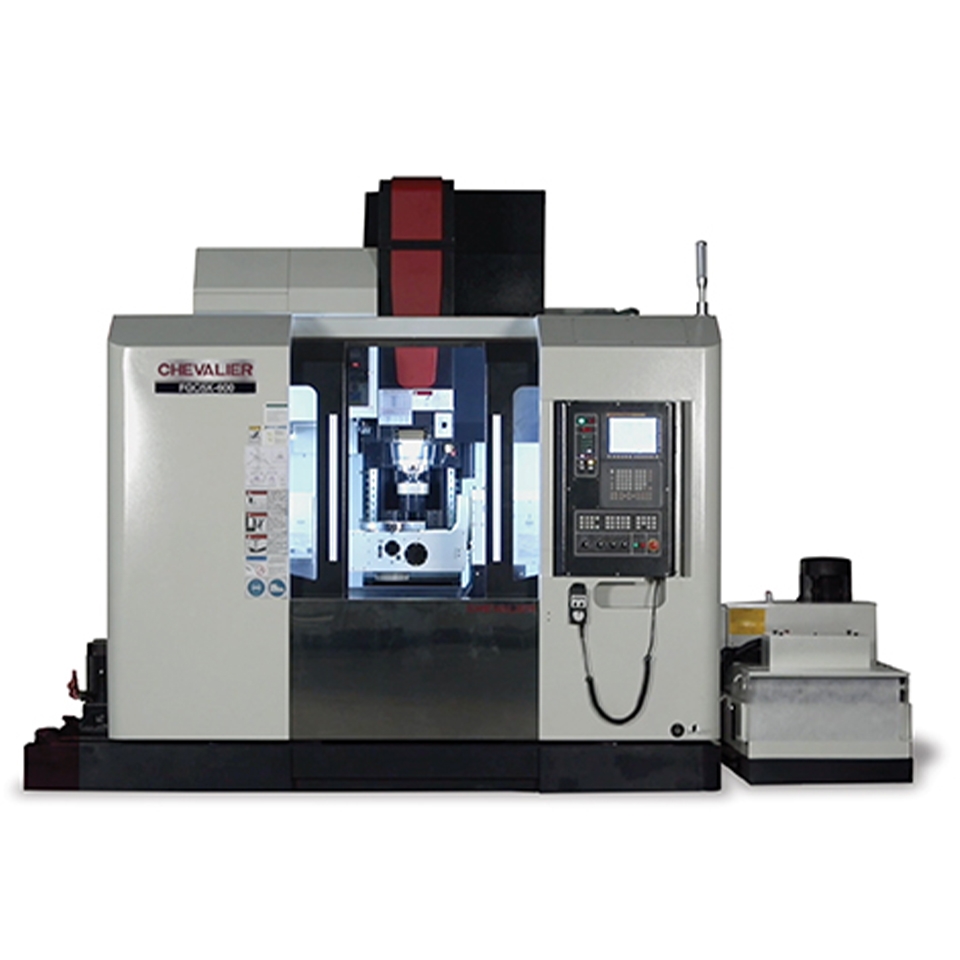

FGC5X-600

Product Introduction

The machines are shown with optional accessories.

- 5-axis surface and profile CNC grinding center

- Benefit of the 5-axis grinding center is performance of several operations in a single setup

- Precision direct drive spindle

- Capable of producing highly accurate workpieces with complex geometry

- All guideways are protected from grinding swarf

- Dual chip augers to remove large waste material

- ATC 40 taper tool holder

- Capable of accepting aluminum oxide wheels

- Automatically compensates for the dress amount

- Control: 31i-B5 full 5-axis control

| ITEM | Description | S.A.E. | Metric |

|---|---|---|---|

| Control | Fanuc-31i -B5, full 5-axis | – | – |

| Capacity | Max. table diameter | ø 12.6" | ø 320 mm |

| Max. table load | 220 lbs. | 100 kg | |

| Max. workpiece dimensions | ø 24.0" × H13.8" | ø 610 × H350 mm | |

| Travel | X / Y +travel for tool / Z-travel | 29.5", 24.0", 21.7" | 750, 610, 550 mm |

| Feed rates | Rapid traverse (X/Y/Z) | 1,417, 1,417, 1,181 ipm | 36、36、30m/min |

| Cutting feed rate | 394, 394, 394 ipm | 10、10、10m/min | |

| Rotary axis | A-axis - rotation | +30° ~ -120° | +30° ~ -120° |

| A-axis - speed | 16.6 rpm | 16.6 rpm | |

| C-axis - rotation | 360° | 360° | |

| C-axis - speed | 25 rpm | 25 rpm | |

| Spindle | Spindle type | CT40 (BIG PLUS) | CT40 (BIG PLUS) |

| Spindle speed | 12,000 rpm | 12,000 rpm | |

| Spindle motor | 20 HP | 20 HP | |

| ATC & tool magazine | Tool storage | 30 T | 30 T |

| Max. tol diameter with adjacent tool | 3.0” | 76 mm | |

| Max. tol diameter without adjacent tool | 5.9” | 150 mm | |

| Tool length | 11.8" | 300 mm | |

| Tool weight | 15.4 lbs. | 7 kg | |

| Wheel dimension | OD x Width x Bore | Ø6"x 0.98" x Ø1.25" | Ø150 x 25 x Ø31.75 mm |

| Dimension/Weight | Floor space (W x D x H) | 127.1" x 90.0" x 124.0" | 3,230 x 2,287 x 3,150 mm |

| Net weight | 17,500 lbs. | 7,950 Kg |