Jones Machinery 2022 Open House

5/19/2022 Cincinnati, OH

ABOUT THE EVENT

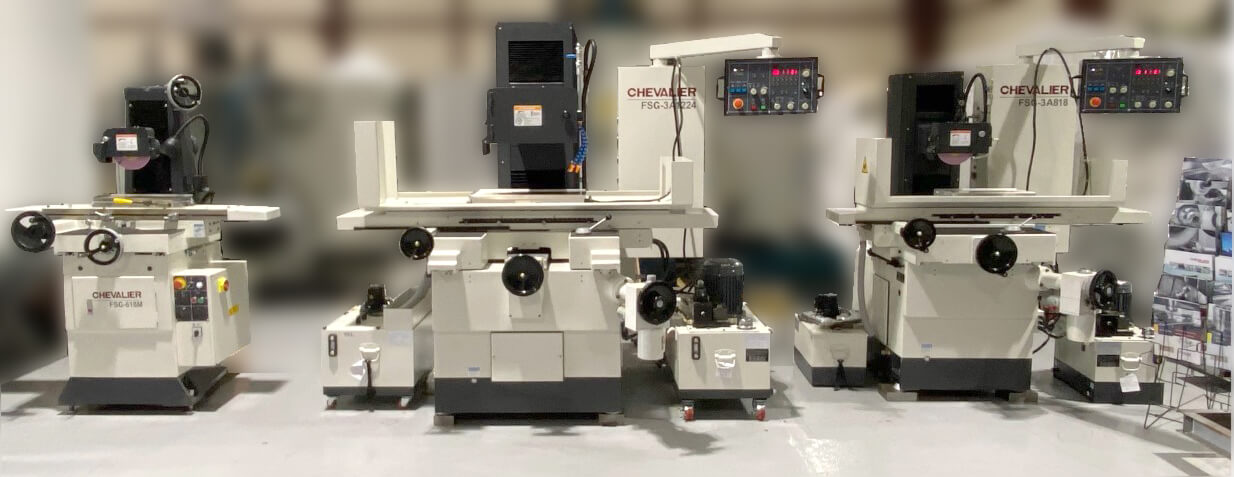

Chevalier’s FSG-3A1224, FSG-3A818 and FSG-618M were exhibited

Representing Chevalier was Johnson Lan, Vice President & Head of Grinding Systems and Kanon Shiu, Product & Service Engineer. Chevalier showcased the FSG-3A1224 and FSG-3A818, both automatic grinders that offer high-performance precision surface grinding and our FSG-618M manual grinder.

PRODUCT SPOTLIGHT

FSG-3A1224 and FSG-3A818

Features Include:

- Series has been specially developed and improved in order to continuously offer reliable high-performance precision surface grinding.

- Double-V crossfeed guideway span has been designed applying kinematics to calibrate minimum bending movements to achieve maximum support for table and workpiece.

- All high-grade cast iron is stress-relieved by annealing to ensure superior stability and rigidity and high-precision surface grinding.

- Maximum distance from table surface to spindle centerline is 450 mm (17.7"), which provides more clearance for grinding (FSG-3A818).

- Table travel for each workpiece can be easily set by using the electronic non-contact reverser, which saves grinding time and delivers higher grinding efficiency (FSG-3A1224).

FSG-618M

Features Include:

- Maximum distance from the table surface to the spindle centerline is 450 mm (17.7"), which provides more clearance for grinding.

- Spring-loaded-type table travel stops will dampen the over-travel caused by abnormal operations.

- Optimum span of double-V crossfeed guideways is designed based on bending movement, kinematics and supporting force.

- All essential castings are high-grade cast iron, stress-relieved by annealing, to eliminate internal stress.

- With the impressive stiffness and stability of its castings, this machine is suitable for both precision surface grinding and form grinding.